Mines are an industry with high energy consumption and high emissions, and in mine production, there is often a large amount of low temperature wind in the mine air. Although this type of ventilation cannot be directly used for heating or other thermal energy utilization, if it can be effectively utilized, it will bring good benefits to energy conservation and emission reduction in mines. The exhaust heat pump system, as an effective means of utilizing waste heat from exhaust air, is being adopted by more and more mines.

What is the exhaust heat pump system?

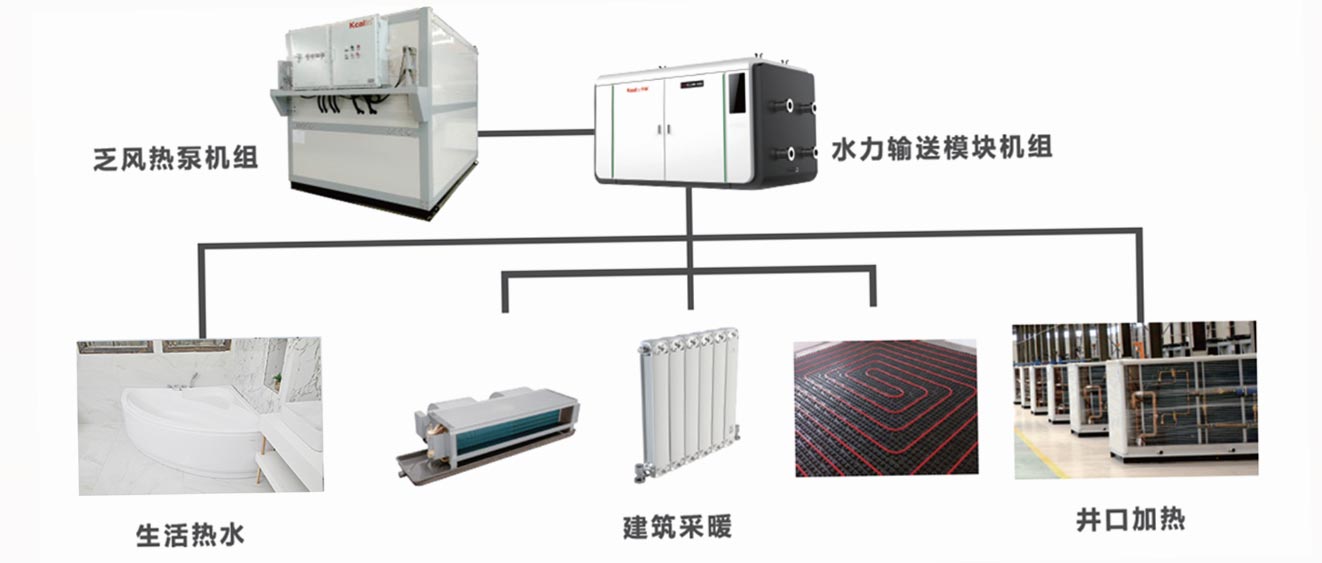

The exhaust heat pump system is a system that utilizes low-temperature energy from mine exhaust air for thermal energy conversion. This type of system usually includes main components such as evaporators, compressors, and condensers. Through processes such as evaporation, compression, and condensation during cyclic operation, the low-temperature energy in the exhaust air is converted into high-temperature thermal energy for heating, hot water production, and other purposes. The exhaust heat pump system can effectively utilize the low-temperature energy in the exhaust air, achieve energy-saving and environmental protection effects, and is also an important means of energy conservation and emission reduction in mines.

The exhaust heat pump system mainly includes the following main components:

Evaporator: located in the channel of the depleted air, it absorbs the low-temperature heat in the mine air through the evaporation process and converts it into low-temperature steam.

Compressor: Compresses low-temperature steam to increase its temperature and pressure.

Condenser: releases heat from high-temperature and high-pressure steam through the condensation process, converting it into high-temperature hot water or steam.

Expansion valve: controls the flow rate of refrigerant to enter the evaporator and form a closed cycle.

The working principle of the exhaust heat pump system is based on the principle of thermal cycle. When the mine air passes through the evaporator, due to the low temperature of the refrigerant inside the evaporator, the heat in the mine air will be absorbed, and the refrigerant will evaporate into low-temperature steam. Subsequently, the low-temperature steam is compressed by the compressor, and the temperature and pressure increase, becoming high-temperature and high-pressure steam. At this time, the high-temperature and high-pressure steam passes through the condenser, releasing heat and becoming high-temperature hot water or steam, which is used for heating and hot water production needs in mines. Throughout the process, the refrigerant continuously circulates, achieving effective utilization of low-temperature energy in the exhaust air.

The advantages of exhaust heat pump systems

Energy conservation and environmental protection: The exhaust heat pump system utilizes low-temperature energy from mine exhaust air for thermal energy conversion. Compared with traditional heating methods, it significantly reduces reliance on fossil fuels, reduces energy consumption and emissions, and reduces greenhouse gas emissions, achieving energy-saving and environmental protection effects.

Comprehensive utilization of resources: The mine exhaust heat pump system effectively utilizes the low-temperature energy in the mine exhaust, achieving comprehensive utilization of resources and avoiding energy waste.

Reduce operating costs: The exhaust heat pump system operates stably and has low maintenance costs. Once the system is built, regular maintenance and upkeep are required to provide long-term and stable thermal energy for the mine.

Improving mine safety: By providing stable heating to the mine, the exhaust heat pump system can ensure that the mine can maintain a suitable temperature even in cold winter, avoiding safety hazards caused by icing.

The application of exhaust heat pump system as an efficient, energy-saving, and environmentally friendly energy utilization technology in mines is of great significance. It not only effectively utilizes low-temperature energy in the exhaust wind, reduces energy consumption and emissions in mines, but also improves the safety and stability of mines. In the future, with the continuous progress of technology and the improvement of environmental awareness, the exhaust heat pump system will play an increasingly important role in the green development of mines, contributing to the sustainable development of mines. Choose a exhaust heat pump system to assist in the green development of mines and build a beautiful environment together!

Comment