Chemical enterprises are synonymous with large sources of pollution and energy consumption, especially in terms of energy consumption. Their thermal efficiency is very low, generally only about 30%, while the heat taken away by high-temperature flue gas, high-temperature slag, high-temperature products, etc. is up to 40% - 60%, of which the available waste heat accounts for about one-third of the fuel consumption.

The waste heat resources in China's chemical industry are mainly concentrated in low-temperature heat energy. The low-temperature waste heat resources are relatively scattered, and the heat transfer temperature difference is small. The recovery value is difficult, but the recovery value is considerable. This type of heat source exists in gaseous and liquid heat carriers. The liquid state is mainly condensed water, cooling water and flammable waste liquid, and the gaseous state is mainly industrial production gas. The waste heat belongs to the secondary energy, which is the product of the conversion process between primary energy and combustible materials, and is the heat generated during the fuel combustion process after completing a certain process. Due to the different production methods, production processes, production equipment, raw materials and fuel conditions and the ever-changing needs of technology, it has brought many difficulties to the utilization of waste heat.

The chemical industry has a complex production process flow and a large amount of waste water, which has high temperature and poor water quality, but can be used to extract waste heat resources after proper treatment. The extracted heat can be used for hot process water or boiler make-up water preheating. Recovery and utilization of this part of energy can not only help solve the energy problem, but also reduce environmental pollution in the energy production process, clean and environmental protection, and reduce enterprise production costs.

The utilization efficiency of waste heat resources in chemical industry is related to the temperature of waste heat resources. Generally, the higher the temperature, the higher the utilization efficiency. According to the temperature of waste heat resources, it can be divided into high temperature waste heat (above 500 ℃), medium temperature waste heat (200~500 ℃) and low temperature waste heat (below 200 ℃). Waste heat boiler power generation is generally applicable to high-temperature waste heat, while heat pump recovery system is applicable to low-temperature waste heat.

1.Cooling circulating water formed by exothermic reaction

2.Cooling circulating water produced by air compressor, refrigerant, etc

3.Wastewater from industrial production

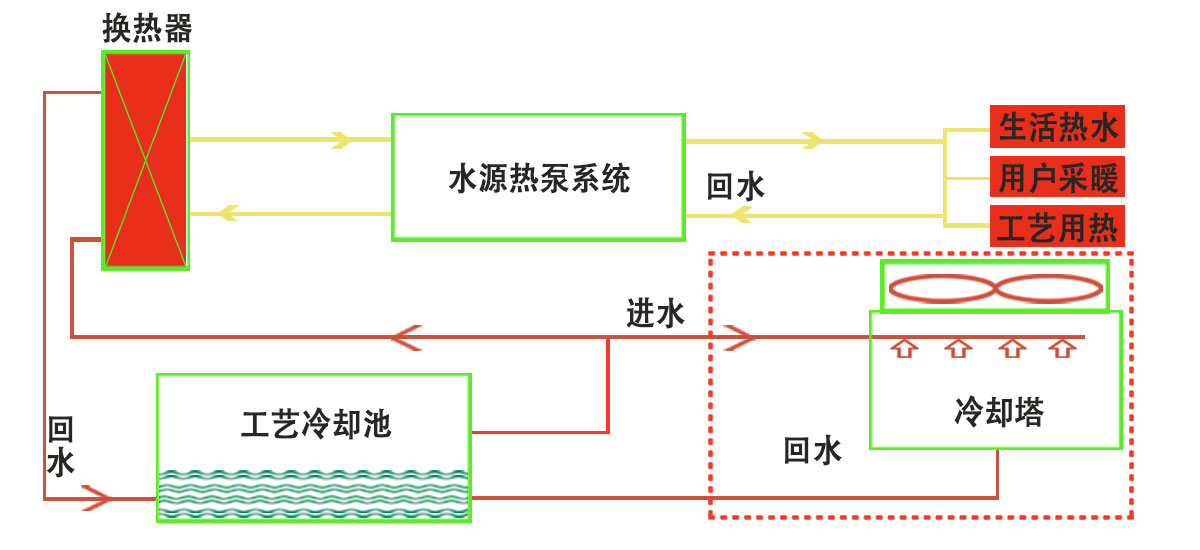

High temperature water source heat pump is a kind of high temperature heat pump. It uses the waste heat in the waste water of the chemical industry to produce 70 ℃~90 ℃ hot water for energy conversion of the heating and air conditioning system. After the waste water passes through the heat exchanger, the cooling capacity or heat is returned to the waste water channel. The waste water does not contact with other equipment or systems. The waste water is closed and does not pollute the environment and other equipment or water systems. The boiler room systems such as coal, gas and natural oil are omitted during heating, and there is no combustion process to avoid smoke pollution, which can be directly used for heating and ordinary industrial heating. It does not produce excess waste residue, waste water, exhaust gas and smoke, and has obvious environmental benefits.

1.Use water source heat pump to extract low-grade heat from cooling circulating water to provide process heating

2.Using water source heat pump to extract low-grade energy from cooling circulating water and industrial waste water for heating buildings

1.Reduce operating costs by more than 30%

2.Static investment recovery rate 3-5 years

3.More than 50% of energy saving and emission reduction rate

Recommendations

Thermal power industry waste heat utilization solution

Solution to mine high temperature heat hazard

Solution for waste heat utilization of mine exhaust air

Heat Pump Dryer

Difference for air source heat pump and air conditioning

Climb high, look at the sea, speak clearly, travel, cultivate the mind, and learn to practice

Comment