There are a large number of waste waste heat resources that can be utilized in the production process of the mine, such as wellhead exhaust, underground water inrush, residual heat of the pressure fan, etc; However, many places in the mining area need heat sources, such as anti-freezing at the air inlet, domestic hot water and building heating in the mining area. At present, most mining areas still use traditional coal-fired boilers for heating, but this heating method has serious air pollution, low heating efficiency, large energy waste, poor labor environment, high operating costs, and many potential safety hazards, which is incompatible with the national "double carbon" strategy and "coal to electricity" policy.

So, is there any equipment that can recycle the above waste heat to meet the heating demand of the mining area?

The answer is yes, that is, the heat pump unit for waste heat recovery of mine exhaust air of Kcalin Company.

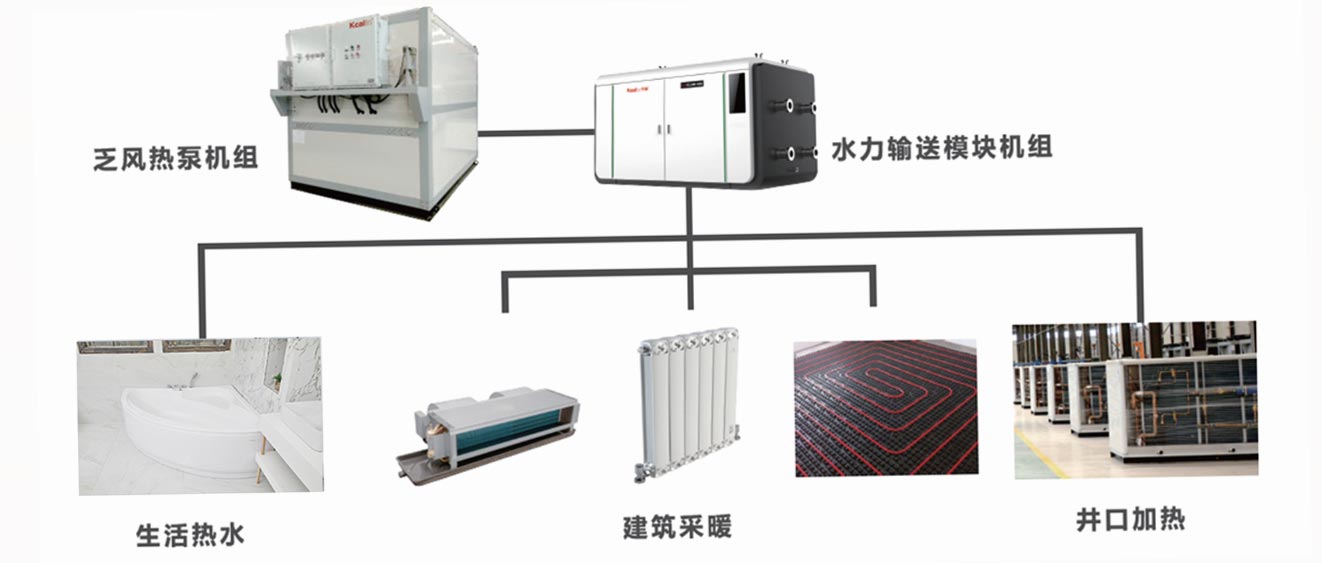

The waste heat recovery heat pump module unit of Kcalin mine exhaust air can recover the waste heat of the mine exhaust wellhead, the water source heat pump unit can recover the waste heat of the mine water inrush, and the waste heat of the compressed air fan can be recovered by the waste heat recovery unit of the compressed air fan. The unit is easy to install and use, and the heat after heat recovery can be used for domestic water, building heating, wellhead antifreeze, etc.

The exploration and practice of waste heat resource utilization in China's coal mines started in the mid-1990s and rose in the beginning of this century. After nearly 20 years of development, various technologies for waste heat utilization in coal mines have emerged in endlessly. After the survival of the fittest in the market practice, the waves washed out the sand. The whole set of "comprehensive solution for green cooling and heating system in coal mines" process package proposed by the Kcalin heat pump technical expert team has also experienced the practice of many green cooling and heating projects in coal mines for more than 20 years, The waste heat utilization technology of coal mine exhaust air has gone through four generations. At present, the process package has been proven to be mature and reliable in performance, energy conservation and environmental protection, and has a wide range of applications. It is an ideal choice to realize the national "double carbon" strategy and the "coal to electricity" policy.

Working principle of Kcalin heat pump unit for waste heat recovery of exhaust air in Mine

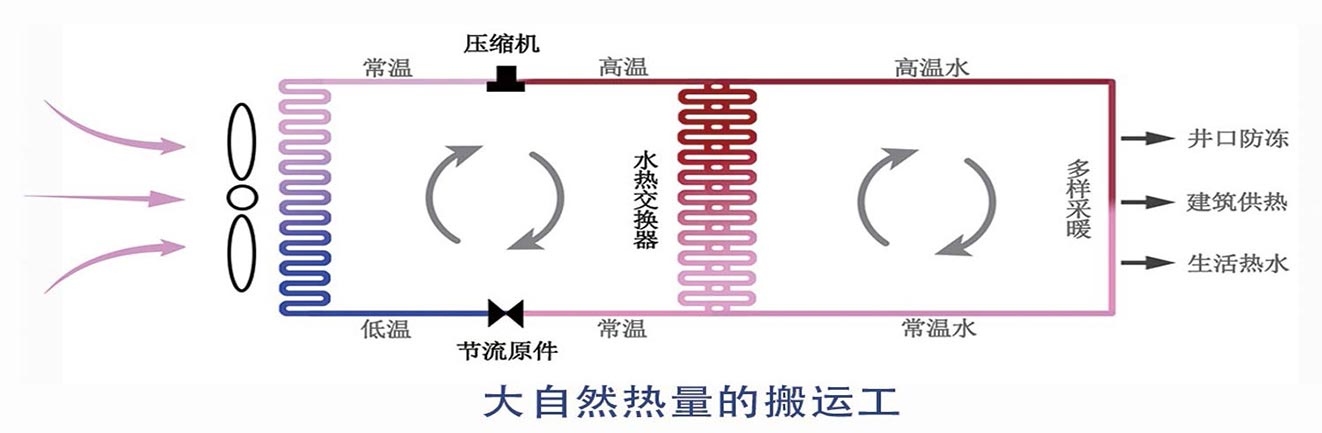

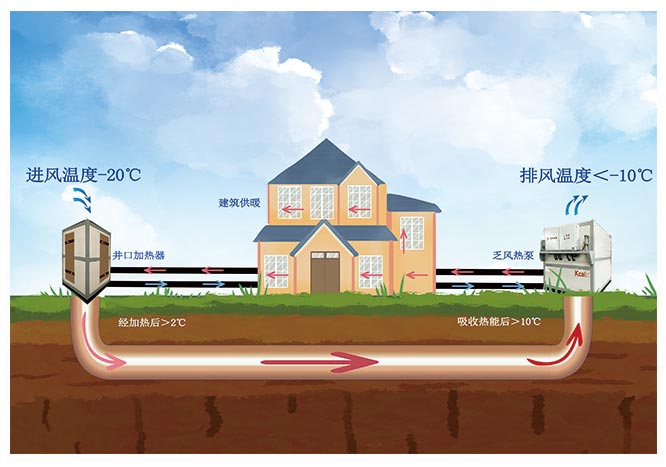

The exhaust air of the mine is affected by the geothermal energy and contains a large amount of low-grade heat energy. The Kcalin mine exhaust air waste heat recovery heat pump module unit works according to the "inverse Carnot" principle, and takes the refrigerant as the carrier to carry the heat in the exhaust air to the heat side continuously to meet the needs of users in terms of domestic heating.

The waste heat recovery unit of the exhaust air is used for heat supply. Its working principle is simply to drive the compressor by consuming 1 part of electric energy, and use the refrigerant to absorb 4 parts of air energy from the exhaust air. Compared with the direct electric heating, it can obtain 3 parts of heat energy& nbsp; The special exhaust air waste heat recovery pump unit for Kcalin Mine is not directly heated by electricity, but the low-grade heat energy in the exhaust air is moved to the room after using the gas-liquid change of the refrigerant to increase the temperature, so as to effectively reduce the operating cost of winter heating for users.

Security Intelligence

Explosion-proof certification has been passed and safe operation is guaranteed

The waste air and waste heat recovery unit for Kcalin Mine is strictly in accordance with GB3836.1-2010 Explosive Atmospheres Part 1: General Requirements for Equipment, GB3836.2-2010 Explosive Atmospheres Part 2: Equipment Protected by Flameproof Enclosure "d", and GB 3836.3-2010、 GB 3836.4-2010 Explosive Atmospheres - Part 4: Equipment Protected by Intrinsic Safety "i" and Explosive Atmospheres - Part 9: Encapsulated "m" (GB 3836.9-2010) are designed and manufactured, and have been inspected by the national quality supervision and inspection department and obtained the "explosion-proof certificate"& nbsp; & nbsp; This product is applicable to flammable and explosive environment, used for heat recovery of exhaust air and providing hot water to users.

Remote Internet of Things intelligent monitoring operation and maintenance platform

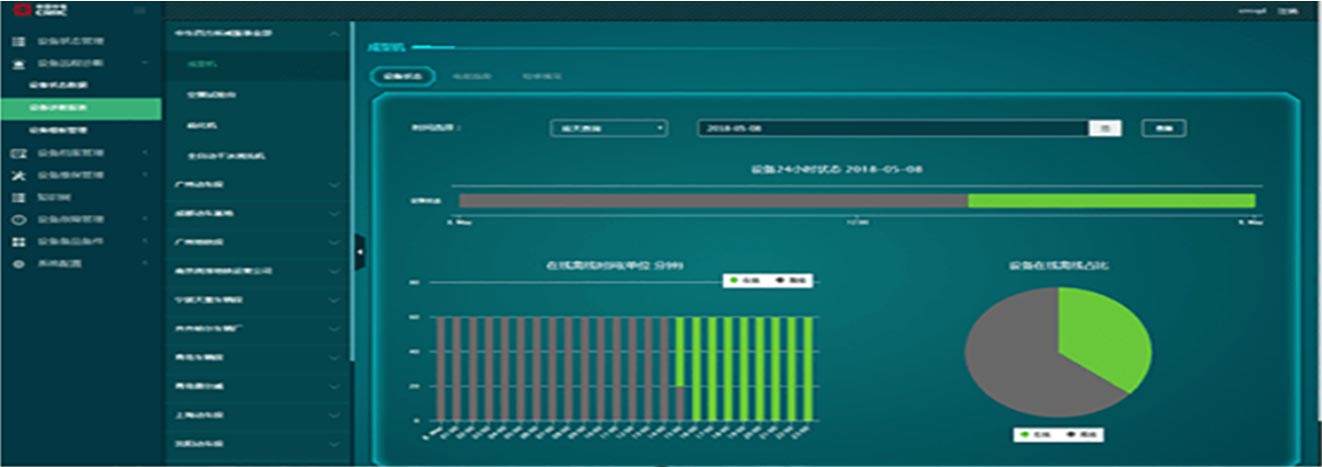

The remote intelligent monitoring, operation and maintenance platform of the Internet of Things independently developed by Kcalin, with the Internet and artificial intelligence as the central technology, has realized the intelligent management of the waste air and waste heat recovery unit. The administrator can use various terminals to log in to the platform through the browser to remotely control the switch, temperature and control parameters of the unit. The specific functions are as follows:

● Big data function: data collection, energy consumption analysis, expert diagnosis ● real-time collection of heat and electricity ● intelligent control, saving manpower and material resources

● Remote monitoring and control: parameter setting, operation status display, automatic fault detection and alarm ● Automatic compensation function of ambient temperature: automatically adjust the supply and return water temperature according to the change of outdoor ambient temperature

Power-off memory function

When the unit encounters a sudden power failure, the unit will automatically return to the operation mode before the power failure after the power failure, and automatically operate according to the parameters before the power failure. If the unit is shut down before power failure, it will still be shut down after power failure.

Adaptive air volume change

In order to adapt to the heat recovery demand of some variable air volume deep well mines, Kcalin has specially set up an electric insulated closed regulating valve for each exhaust air heat recovery unit. When the air volume of the return air shaft changes, some exhaust air heat pump module units can be automatically closed to achieve the design heat supply.

Efficient and energy-saving

Low evaporation temperature

The waste air and waste heat recovery unit of Kcalin Mine can realize efficient heat generation at low ambient temperature by using low-temperature jet enthalpy increasing technology and refrigerant direct evaporation technology. The evaporation temperature of the unit refrigerant is about - 35 ℃. The greater the difference between the evaporation temperature and the exhaust temperature, the higher the heat exchange efficiency and the better the heat exchange effect.

Integral structure, multi-stage heat exchange

The unit adopts integral design. The exhaust air is directly exchanged through the fins of the unit. The heat exchange circuit is short, avoiding secondary heat exchange, and the heat efficiency is higher. The unit can realize cascade heat extraction with large enthalpy difference, and the exhaust temperature can be taken below - 10 ℃ to recover more heat.

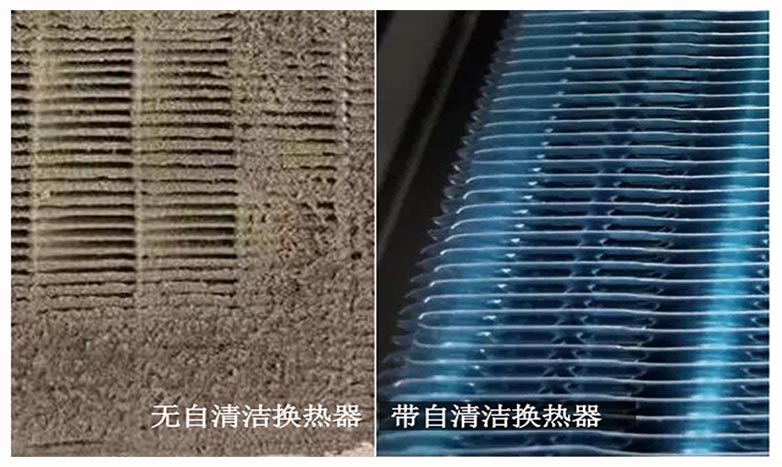

Automatic cleaning of fins, longer service life of the unit

The mine exhaust contains a large amount of high humidity dust, which is easily attached to the fins of the unit, affecting the heat exchange efficiency and service life of the unit. The fin automatic cleaning function specially developed by Kcalin for this purpose can prevent the unit from dust intrusion. The cleaning area and the drainage pipeline are set in the high temperature area of exhaust air, and there is no antifreeze problem.

Green and environmental protection

The unit adopts environmental protection refrigerant R410a, which has a damage coefficient of 0 to the atmospheric ozone layer. It is green and environmentally friendly, with high heat transfer coefficient and low pressure loss, and improves the energy efficiency of the system. R410a refrigerant has more heat capacity per unit volume. The same heat exchange can use less refrigerant, reduce the global greenhouse effect, save energy and reduce emissions; In line with the sustainable development strategy.

Convenient installation

Modular construction

The exhaust air and waste heat recovery unit of Kcalin Mine adopts modular design, which can calmly cope with the mine with different air volume and heat demand. The units can be installed in batches according to the progress of the project, with strong expansibility and reducing the initial investment of the project.

Desalination of main and sub-module design

In a modular control system, each unit can be used as the main module to communicate with other units and coordinate the whole system to work as required. When the product can only be designed with fixed unit as the main module, if the main module is damaged, the whole system can not work normally, and the commissioning and maintenance are not convenient.

Recommendations

Thermal power industry waste heat utilization solution

Energy saving solution for crude oil heating

Solution for waste heat utilization in chemical industry

Air Purification System

Application of Kcalin air source heat pump in agricultural drying field

Time flies, wind and rain go together, Kcalin, seven years old!

Comment